Main Application

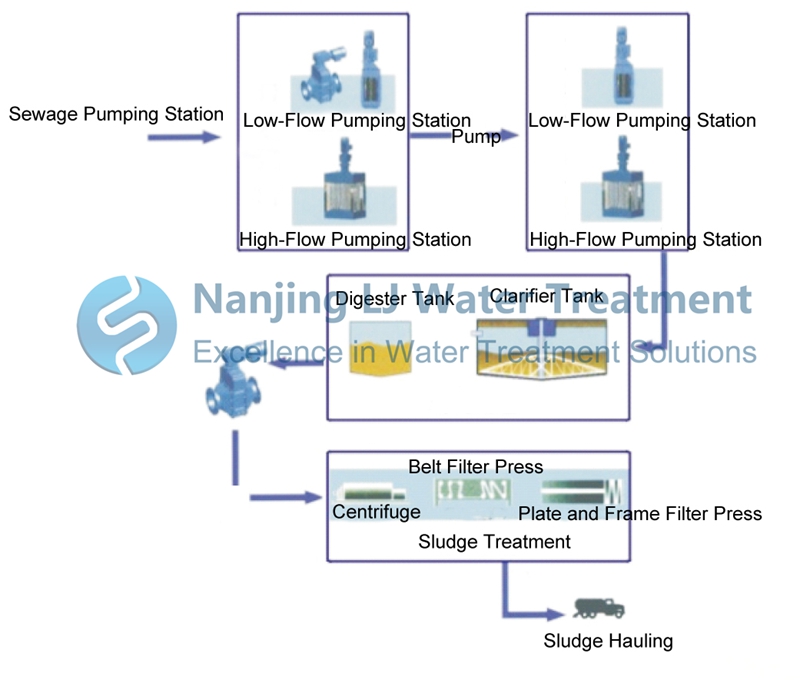

lSuitable for installation in front of sewage pumps to crush solid materials.

lSuitable for installation behind bar screens to crush floating substances fished out of water.

lSuitable for installation in front of incineration equipment to crush waste into sizes convenient for transportation.

lSuitable for sewage treatment pipelines to crush solid substances mixed in sludge.

lUsed for crushing recycled items such as empty cans, batteries, and plastic products.

Product Features

lIntegrated design, featuring a compact and aesthetically pleasing appearance.

lFlexible structure and multiple installation options, adaptable to channels of various sizes.

lAdopts low-speed operation, resulting in low wear rate and low power consumption; utilizes the principle of dual-shaft differential speed to achieve crushing through force and extrusion.

lSpecial structural design provides excellent self-cleaning capability, with no winding or debris accumulation.

lStable head loss ensures consistent water depth upstream and downstream.

lUnique transmission structure facilitates easy replacement of wearing parts (such as blades), simplifying maintenance and reducing maintenance costs.

lHigh-grade alloy or stainless steel cutter heads ensure high working efficiency and reliability of the equipment.

lOptimized design guarantees high efficiency and low energy consumption.

lReliable protection system: when the equipment is overloaded, it automatically reverses to unload; if the fault cannot be resolved after three retry attempts, it shuts down and triggers an alarm.

lAmphibious motor, suitable for both land and water use. The motor can operate normally indoors and outdoors, and can also be used submersibly when the water level rises suddenly.

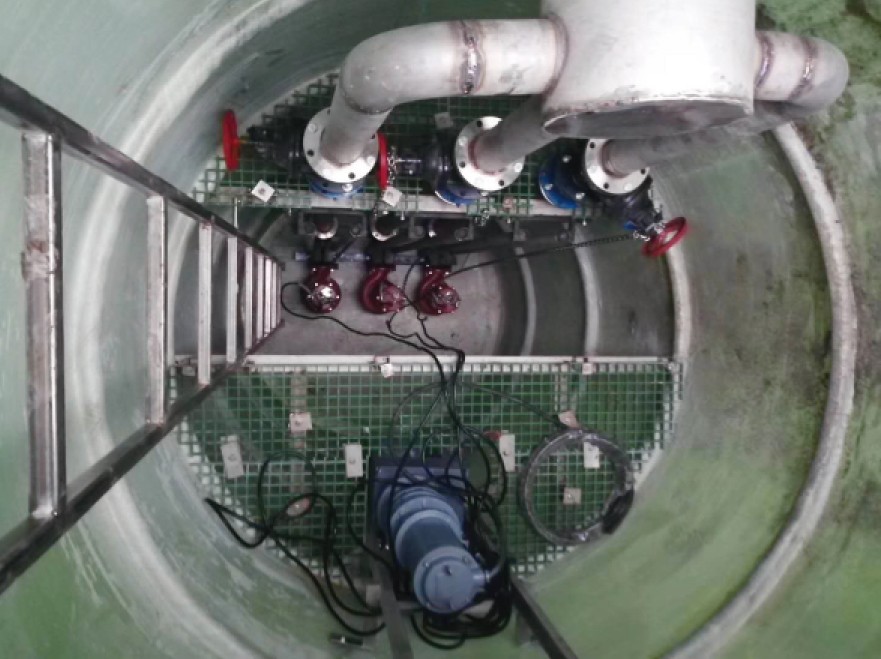

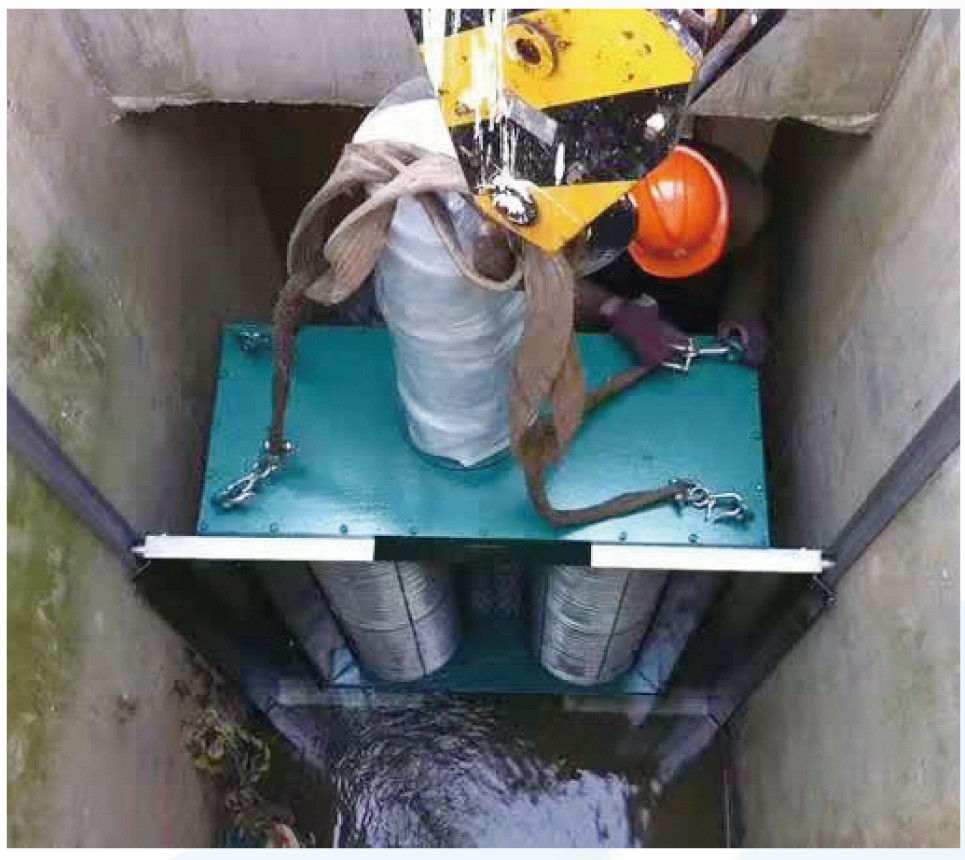

lSelf-coupling installation for easy maintenance. The grinder works underground; with the self-coupling installation design, no large lifting equipment is required. During maintenance, the entire equipment can be lifted out of the pool via lifting rings for inspection and repair.

lSmall floor space and low overall investment. The equipment is fully buried underground, with small size and light weight; no dedicated building is needed, resulting in low civil engineering costs.

Main Structure

The equipment mainly consists of the following components: amphibious motor, reducer, machine body, cutting blades, gaskets, dual rotating shafts, intermediate support shaft, mechanical seal device, machine base, vertical rotating water-passing drum screen, automatic coupling device, overflow screen, and maintenance screen.

lCutting blades & Gaskets: Alloy steel, stainless steel

lShafts: Heat-treated hexagonal alloy steel

lBase & Housing: Cast iron, stainless steel

lSide Rails: High-quality carbon steel

lRubber Parts: Nitrile rubber (NBR)

lDual-purpose Motor: 2.2kw - 7.5kw