Main Application

GSLG Screw screens are versatile in both municipal and industrial wastewater treatment scenarios:

Municipal Sector: Urban sewage treatment plants, intake structures, and pumping stations.

Industrial Fields:

Food industry: Including meat processing, vegetable and fruit processing, and general food manufacturing.

Specialized industries: Pulp-and-paper mills, tanneries, breweries, textile mills, and slaughterhouses.

Others: Process water treatment in various manufacturing plants.

Working Principle

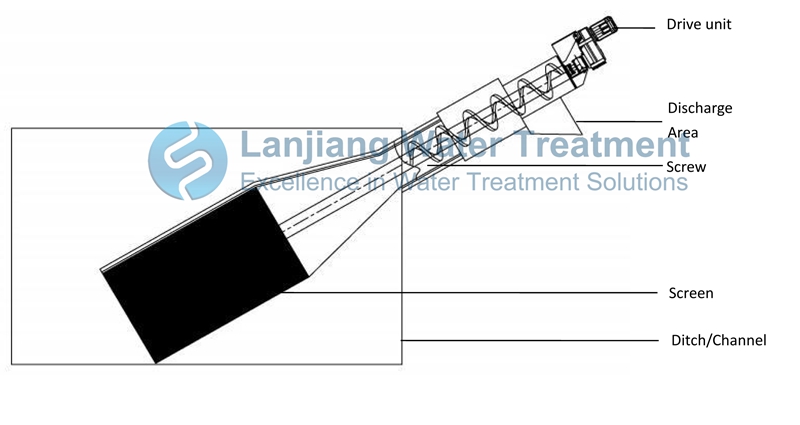

The screw screen operates through a systematic solid-liquid separation and self-cleaning process:

Filtration Stage: Wastewater flows through a cylindrical screen basket (made of wedge-wire or perforated plate). Solids (floating, precipitated, or suspended) are retained on the inner surface of the screen.

Cleaning Mechanism: When the water level difference across the screen reaches a preset value, a rotating slag-scraping rake or screw conveyor (with brushes) cleans the screen gaps, dislodging trapped solids.

Transport & Dewatering: The removed solids are conveyed upwards by a screw mechanism. During this process, they undergo compaction and dehydration (with optional washing for high-organic-content residues), resulting in a solid content of up to 40%. The entire cycle is automated, ensuring no clogging and continuous operation.

Structural Advantages

Material & Durability: Constructed from corrosion-resistant stainless steel (via key parts pickling and passivation), ensuring long-term use in harsh wastewater environments.

Design Flexibility: Available in different screen spacings (0.25mm–12mm) and basket sizes (up to 3000mm in diameter) to match project-specific needs. It can be installed directly in channels or within boxes.

Operational Efficiency: Features mandatory self-cleaning via rotating components, low head loss, and large processing capacity. The closed-system design eliminates odor pollution, while integrated filtration and dewatering reduce investment and maintenance costs.

Integrated Multifunctionality: Combines screening, transportation, flushing, and dehydration pressing in a single compact unit, eliminating the need for separate conveyors or presses and reducing overall costs.

Operational Stability & Odor Control: The closed-system design prevents odor pollution. The self-cleaning mechanism avoids clogging, ensuring reliable operation even under varying loads.

Parts in Warehouse